PACOPAD

Description

- Proven worldwide performance since 1986

- Operating temperature of 475°F/246°C for six hours

- Two standard thicknesses of .035” (.89mm) and .055”(1.4mm) for custom Heat Input Control and optimal Pressure Equalization

- Extremely low moisture to reduce liquid buildup in vacuum systems minimizing heat rise variability due to volatility

- Uniform fiber formation and distribution for unmatched pressure equalization, micro Z-axis conformance and repeatable, consistent Heat Rise

- Low fiber dusting and contamination

- No resinous binders or fillers, essentially sulfur free, with no odor or solvents to pollute vacuum systems or the work environment

- Environmentally friendly – suitable for re-pulping, land fill disposal or incineration

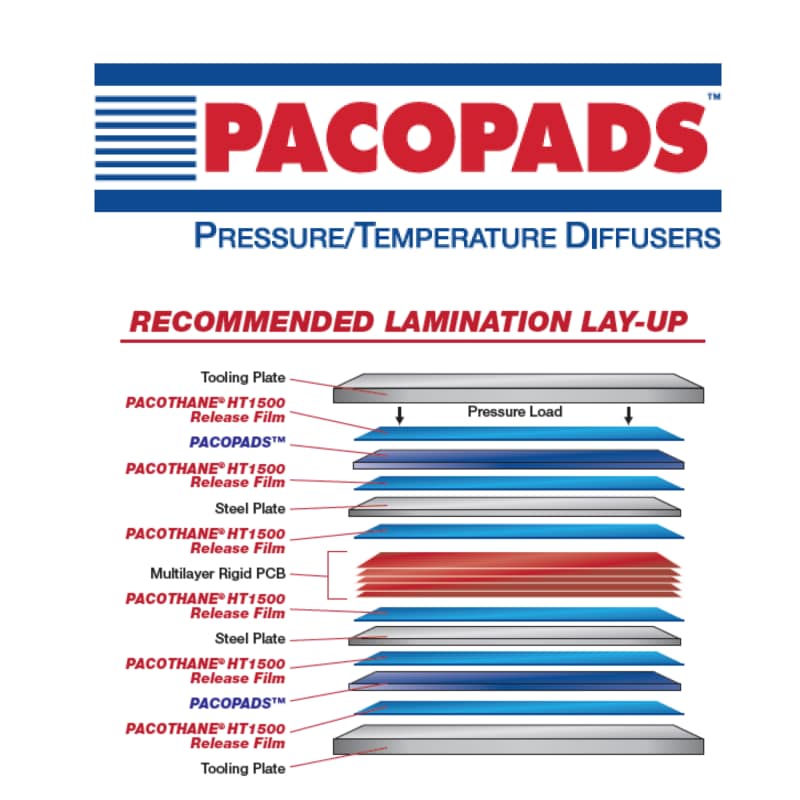

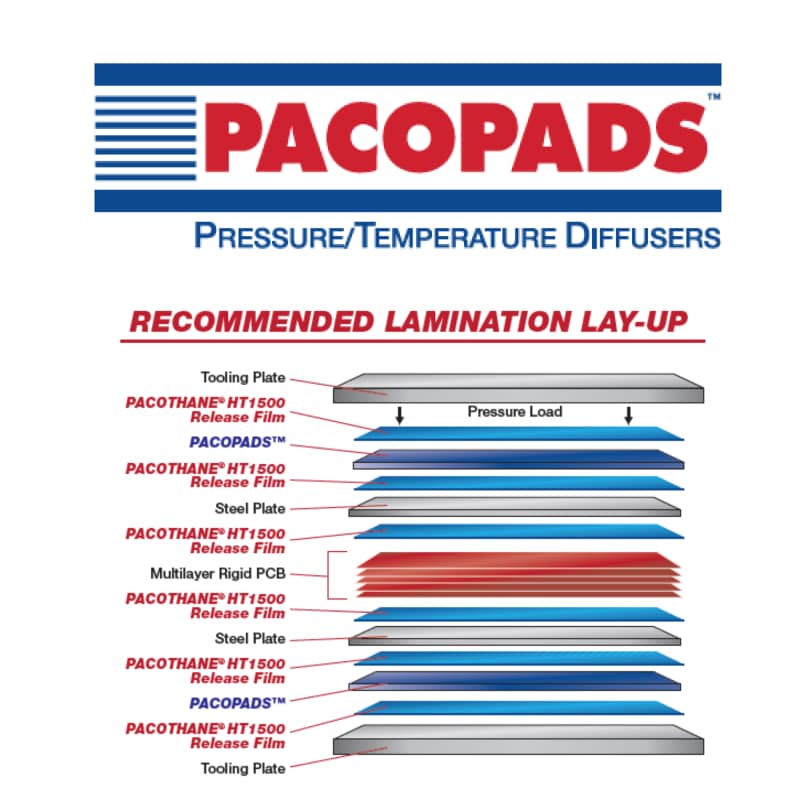

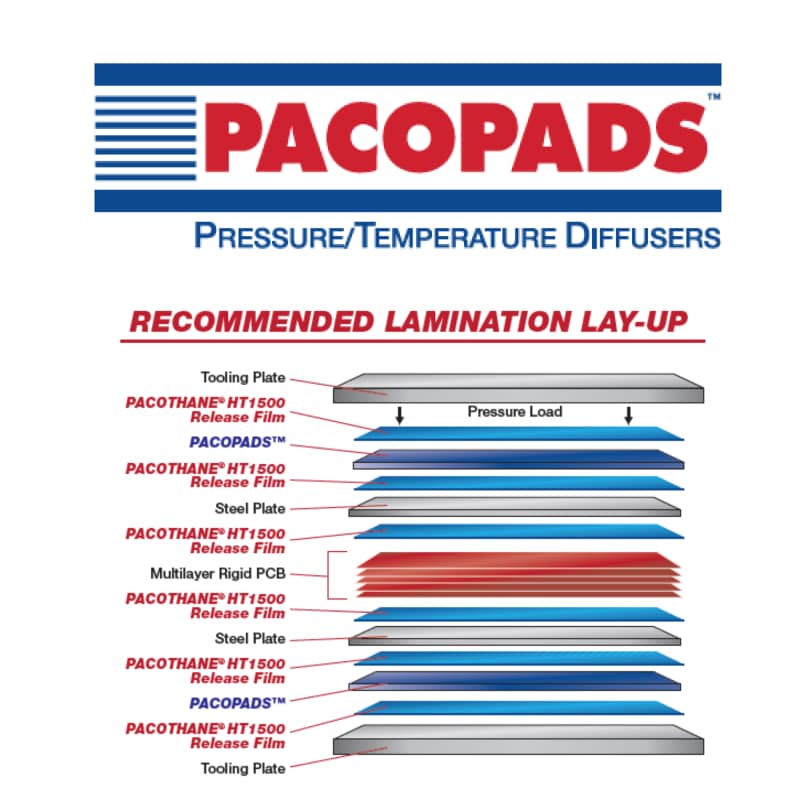

PACOPADS™are a line of press pads specifically engineered to improve the process of laminating rigid multi-layer and flexible Printed Circuit Boards. They serve two primary functions: to accurately control heat input and to equalize the pressure applied

to the panel surface. PACOPADS™ are a unique, cellulosic-based product, engineered specifically to meet the performance requirements of both Rigid Multilayer and Flexible Printed Circuit Board manufacturers. PACOPADS™ are manufactured on a highly specialized paper machine, using virgin fibers that guarantee a low density profile consistent across the entire area of the sheet. (See Press Probe Illustration) PACOPADS™ are vastly superior to commodity grade papers which vary significantly in weight, thickness, hard spots, contaminants, and moisture.